Most of today’s consumers have a vast selection of options available to select from when it pertains to comparable products and services. A product’s QFD can be analyzed in regards to efficiency, toughness, as well as integrity, as well as most customers make their selections based upon a general perception of value and quality function deployment.

Quality is a vital specification that sets a company or service aside from its market competitors. The Six Sigma Green Belt Training Online is an accreditation training course that conveys an understanding of the significance of quality function deployment assurance procedures in a company.

It concentrates on supplying a remarkable top quality product by establishing a process-oriented overview of Top quality Management and encompassing the Complete Top quality Monitoring (TQM) system. In this context, it is essential to understand what is QFD or quality function deployment Feature Release.

Requirement for Quality Function Deployment

First, let’s attend to one of the most pertinent questions- what is the demand for Quality Management? Nevertheless, what is the point of making a Green Belt training qualification without comprehending the significance of High-quality Monitoring?

So below’s exactly how quality function deployment can assist your company to expand:

Top-quality Administration devices help companies to make and also produce products that line up with the consumer’s desires and needs, ensuring the customer’s complete satisfaction.

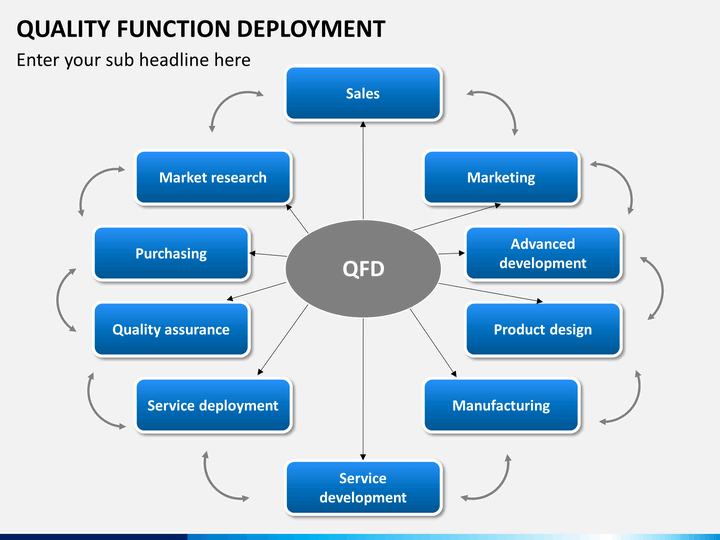

By executing quality function deployment techniques in various industries, consisting of research study, sales and advertising and marketing, manufacturing, financing as well as accounting, management, and device maintenance, organizations can make sure reduced prices and boosted revenues in time.

Company insurance coverage and also data security are insufficient to minimize the possibility of threats. For instance, remembers can cause financial losses, injured the brand online reputation, and negatively influence the consumer’s experience. Therefore, organizations need to adopt Quality Monitoring practices to reduce threat opportunities.

When risks are lessened, products will be consistently created to satisfy the highest standards of resilience, integrity, and also performance. As a result, staff member spirits are boosted with enhanced efficiency, raised earnings, and boosted efficiency.

Last but not least, a sound quality function deployment helps services provide superior-quality products and keep a one-penmanship while maximizing cost-efficiency and also source utilization.

What is QFD?

Developed in the 1960s by Yoji Akao of Japan, QFD, or High-Quality Feature Release is a collection of devices as well as procedures that efficiently specify the consumer’s requirements and also converts them right into sophisticated engineering plans and specs to create products that satisfy those needs.

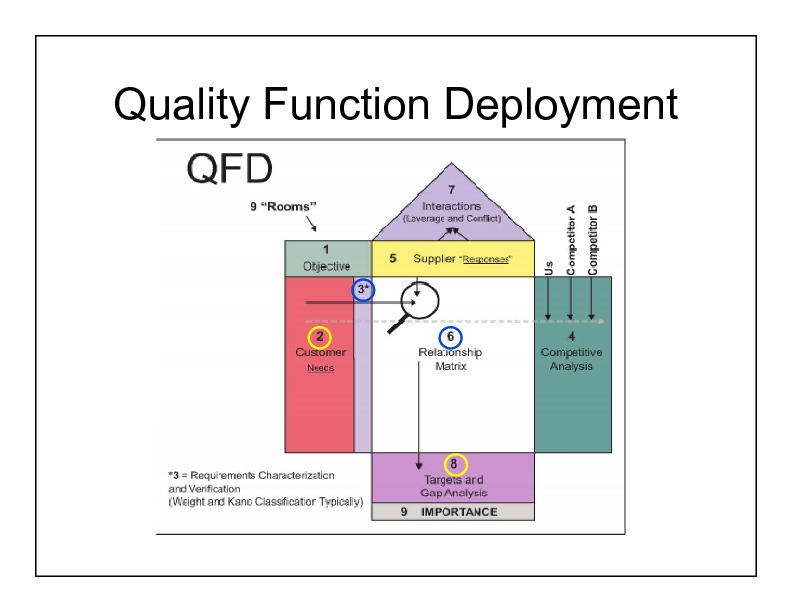

In simple words, quality function deployment focuses on the consumer’s requirements throughout the whole process of item development. QFD converts the Voice of Consumer (VOC) or client’s needs right into quantifiable product layout targets and drives them with each level, from setting up with handling and last manufacturing. Adhering to is a visual illustration of the QFD product preparation matrix or “residence of top quality” that demonstrates how the client’s demands are directly associated with the methods companies can use to attain those demands.

In simple words, quality function deployment focuses on the consumer’s requirements throughout the whole process of item development. QFD converts the Voice of Consumer (VOC) or client’s needs right into quantifiable product layout targets and drives them with each level, from setting up with handling and last manufacturing. Adhering to is a visual illustration of the QFD product preparation matrix or “residence of top quality” that demonstrates how the client’s demands are directly associated with the methods companies can use to attain those demands.

QFD was first used in Mitsubishi’s shipyard, as well as with time, it got embraced by businesses like Toyota and also its supply chain. It was the very early 1980s when QFD was introduced in the USA by electronics manufacturers and the automotive business. Ever since, QFD has gotten approval as well as popularity as well as is currently being utilized across the manufacturing, service, and health care markets.

QFD Technique

The quality function deployment method is a 4-step procedure including activities throughout the whole cycle of item growth. At each phase, a collection of matrices equates the VoC to create requirements for every system as well as components.

1. The first stage is all about specifying the item. In this stage, VOC is gathered, as well as the customer’s demands, as well as requirements, are translated right into product specifications. The first design is based upon the requirements as well as the performance requirements of a certain item. The initial stage may additionally consist of an affordable examination to examine how reliable the rival’s product goes to meeting the client’s assumptions.

2. The 2nd phase requires item growth. The important item qualities are determined and also translated right into essential parts as well as assembly features or requirements in this stage. After that, the practical requirements are defined for every operational level.

3. The 3rd phase requires the advancement of the process. During this phase, the assembly, as well as production processes, are developed based on part and item specs. So, this stage includes the development of the process flow as well as the recognition of fundamental process characteristics.

4. The last stage entails the Quality Control assessment of the process. So, before the product launch, the Quality Function Deployment process identifies the crucial part and process attributes. Process specifications are decided, and also ideal process controls are established and also employed. Full production starts after the procedure ability research studies are completed throughout the pilot development.

Why Implement QFD?

Smooth and efficient interaction is just one of the most impactful variables that drive an organization to success. The QFD methodology is developed to successfully connect the consumer’s requirements to all the business procedures within an organization, including manufacturing, high quality, layout, sales, marketing as well as manufacturing.

This efficient transmission of the VOC promotes infra-organizational collaboration while generating items that meet the consumer’s perceived concept of top quality and also worth it. There are several various other advantages to executing QFD:

- Product advancement cycles get shorter

- Start-up expenses are substantially reduced

- A valuable device for enhancing the top quality of deliverables

- Besides improving item high quality, QFD helps with the stabilizing of the quality

- An atmosphere of cumulative and synergy is promoted

A means to evaluate exactly how your product prices in contrast to that of your competitor. Decisions and lessons are documented for future referral. QFD permits the identification of the reasons behind the client’s complaints and also assists in prompt as well as remedial activities. Makes it possible for the identification of sales factors that causes substantial market benefits

The essence of the Six Sigma Green Belt training and accreditation depends on welcoming the Total Quality Management System to deliver the products of the finest. High-quality Monitoring is crucial not just to develop the finest products, but likewise to surpass the customer’s expectations, which depend on the item’s perceived high quality in terms of efficiency, robustness, and dependability.

Quality Feature Implementation is one such tool that drives the product layout and manufacturing procedure with the key purpose of satisfying the customer’s needs. In this light, the 6 Sigma Green Belt training is the best means to understand the numerous elements that affect processes and quality.