3D printing is maturing with time, and we are witnessing more serious implementations of this technology. Be it automotive, aerospace, healthcare, or defense, engineers are pushing additive manufacturing boundaries for a complete industrial transformation.

With the evolution of Industry 4.0 adaptation, industries closely follow up with the latest 3d printing trends. Additive manufacturing is offering us more opportunities to make our daily lives productive and value-oriented. As compared to the traditional manufacturing processes, 3d printing brings in a strong dominance of innovation that leads towards higher flexibility.

AM checks all boxes from optimizing manufacturing cost to reducing lead times and catering to bespoke personal and industrial requirements. Below are the latest 3d printing innovations that are beyond conventional anticipations, which are disrupting industries.

Custom Materials

3d printing technology lets engineers go broad with printing filaments. Unlike traditional manufacturing, 3d printing offers a wide range of bespoke filaments ready for printing with robust durability.

The latest material innovation goes beyond fundamental filaments, including nylon, stainless steel, or ABS. Now, engineers are using materials made up of biodegradable recycled materials. Along with this, designers have also found a way to 3d print soft-textured objects using wet paper fibres. These custom-made 3D printers use paper pulp made up of sustainable materials. With the support of such bio-based filaments, the latest 3d printing technologies are also supporting eco-friendly recycling. Some latest innovations in 3d printing filaments that will go mainstream include:

- In the upcoming time, we will see more applications of food 3d printing which can print custom-design chocolates and more. Companies are working towards special 3d printers that can craft modern-art pieces using chocolate as a printing material.

- In the healthcare sectors, doctors can offer more efficient prosthetics to patients with custom filaments.

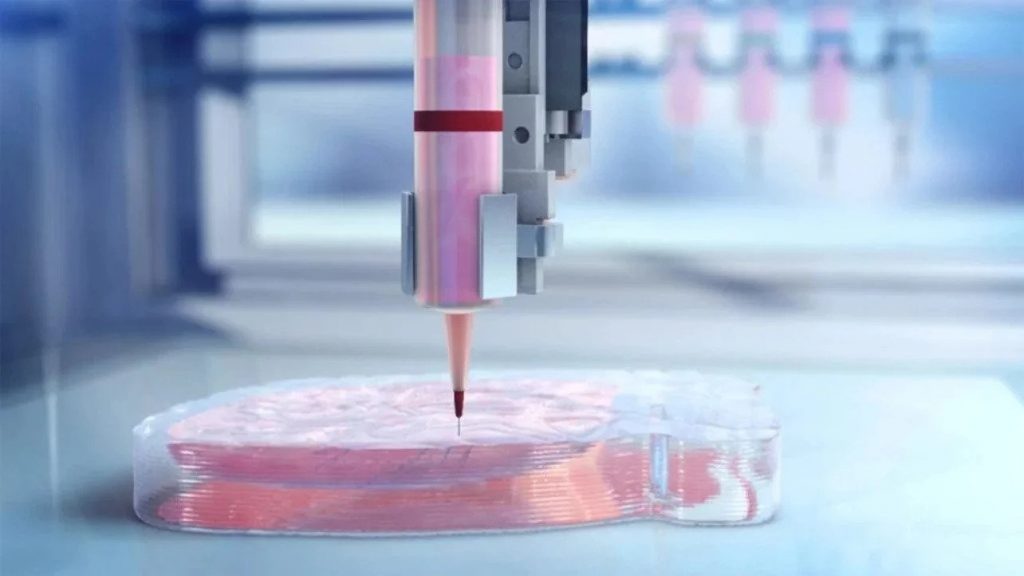

Bioprinting Technology

3D technology is playing a disruptive role in the healthcare industry that disrupts the core with better innovations. 3d printing has gone beyond manufacturing personal protection kits, surgical equipment, and support structures for patients. With the latest advancements, scientists have achieved success in printing a working prototype of a human heart. By using fatty tissues and advanced genetic methods, scientists could turn bio filaments into working tissues.

However, it’s a prototype, but doctors and researchers will soon be able to mass-produce it in the upcoming time. In the future, we can expect companies to print biological compositions like human teeth. This bioprinting innovation will act as a boon for patients who wait for months and even years for the right treatment.

3d printing solving compatibility issues

3d printing will solve the problem of custom parts compatibility with an individual’s body. It often happens that a patient’s body shows side effects after the transplant due to biological imbalance. But with these latest advancements, health institutes can create implants that can match the patient’s bio composition and show no side effects. Some groundbreaking healthcare innovations show us the potential of this technology.

- Researchers have printed artificial hairs using custom 3d printers that are superior to fabricated ones.

- Along with a 3d-printed heart prototype, scientists have also demonstrated a 3d-printed bionic eye. This innovation will be a transformation for blind people.

Improved Prosthetics

Along with bio-printing technology, additive manufacturing is playing wonders in the manufacturing of personalized prosthetics. Earlier and even today, companies manufacture prosthetics with a standard measurement that is not comfortable for every individual. However, 3D printing companies are bringing a core innovation in this healthcare sector.

Now, AM companies can manufacture personalized-fit prosthetics by taking an accurate measurement of the patient. This approach is not only offering more comfort to patients, but they are safer than conventional products. The latest innovation of 3d printed prosthetic goes beyond the static models and provides faster recovery using ultrasonic sound.

Scientists have developed an ultrasonic sound-based cast that can heal fractures with a faster turnaround as compared to traditional plasters. Individuals need to wear this 3d printed cast called ‘Osteoid Cast’ and take ultrasonic therapy for 20 minutes a day. By taking this therapy daily, the healing time improves multiple times without any side-effects. With these advanced prosthetics solutions, additive manufacturing can help with:

- Providing a more comfortable life to patients that struggled for years due to conventional prosthetics.

- Doctors can speed up the healing process and aid patients in going back to their everyday lives with a shorter turnaround.

Emergency Shelters & Military Boats

The 3D printing industry has gone far beyond decorative items and 3d models for representation. Engineers are leveraging advanced printing technologies to 3d print robust military boats and emergency shelters to accommodate individuals.

Using metal 3D printing technology, companies can construct a compact house in less than 48 hours which is a milestone. In emergency accommodation situations, only additive manufacturing can give a ray of hope to people. By using concrete-consistency filaments with recyclable materials, companies can 3d print a house in parts which is easier to transport and assemble in shorter lead times.

Along with robust shelter development, militaries have collaborated with 3D printing service providers to 3d print full-fledged military boats. Manufacturers recently used this technology to produce a heavy military boat that weighed more than 2 tonnes. The manufacturers made this boat in a single-piece in around 72 hours. In the upcoming time, we will notice more prolific applications of AM, including:

- On-demand complex military machinery parts printing in shorter lead times.

- Mass-production of sustainable housings using more durable materials than traditional available options.

Autonomous Mobility

The current transport manufacturing ecosystem is inflexible and highly resource-intensive, which demands substantial land area and resources. Companies are leveraging 3d printing design services and setting up micro-factories for faster and autonomous production to transform this limitation.

Unlike a centralized manufacturing unit, companies split complex operations into multiple smaller factories powered by additive printing machines. With this improvisation, companies can manufacture complicated and more extensive equipment faster and seamlessly.

This latest innovation in manufacturing is helping business owners save substantial cost in materials and resources. As most operations are computer-powered, companies need fewer manual resources to supervise the production. Autonomous mobility in manufacturing using 3d printing will transform the industry with the following benefits:

- Cost-effective mass-manufacturing of complex assemblies in shorter lead times. It will allow businesses to scale operations more efficiently.

- The autonomous approach will bring higher flexibility in traditional production methodology.

Additive manufacturing technology is on the verge of transforming industries with innovative applications. In 2021 and beyond, we will experience more such advancements that will make our lives more productive and comfortable. Several startups and professional companies are offering 3d printing in Brisbane, Sydney and other major cities to support such innovations.